Over several decades, the world has continued to witness intriguing discoveries in medical science, thanks to technological advancements and their applications in medicine. However, in recent years scientists and researchers in medicine seem to have outdone themselves, especially with the discovery of Bioprinting, which enables the fabrication of human organ-like structures that allow cell regeneration. Though this emerging technology in medical science, researchers and scientists are excited to uncover more the full range of applications of Bioprinting as the technology continues to be further developed.

Basics of Bioprinting

Bioprinting is a relatively new approach that has made a significant impact in the field of medicine. Generally, Bioprinting works the same way as 3-D printing, but instead of using artificial materials to print inanimate objects, cells and biomaterials are used to build cells, tissues, and human organs layer by layer. Also, unlike 3-D printing which requires 3D modelling designs, Bioprinting uses layered medical scans of the individual who will be using the printed product.

What are Biomaterials?

Biomaterials are living cells that are retrieved from patients in need of 3D-printed organs. They are the basic requirement for all bioprinted materials. These cells are then cultivated to create bio-ink, which is the substance used to fabricate organ-like structures using 3-D printing technology. However, there are certain cells and tissues that cannot be recreated using Bioprinting. Examples of cells that can be artificially recreated include kidney and skin cells, and an example of cells that cannot be artificially created are adult stem cells.

Bioprinting Techniques

There are five major Bioprinting techniques which can be implemented. These are Extrusion Printing, Laser-based Bioprinting, Microvalves Printing, Inkjet-based Bioprinting, and Tissue Fragments Printing.

- Extrusion Printing – Also known as pressure-based assisted Bioprinting, it is the most common Bioprinting technique. Biomaterial is layered one on top of the other to create a 3D structure. The biomaterials used in extrusion printing are usually pastes and solutions known as bio-ink, which is loaded into a syringe in the extrusion printer, which then prints by forcing the ink out with a piston.

- Laser-based Bioprinting – This technique makes use of a pulsed laser as the energy source to load biomaterials onto a substrate. The process involves the evaporation of liquid biological materials which reach the receiving substrate in droplet form.

- Microvalves Printing – The Microvalve is a simple droplet-based deposition technique where fluids are dispensed under pressure from tips by opening and closing a small elctronicaly or mechanically controlled valve.

- Inkjet-based Bioprinting – This involves a non-contact printing technique that deposits precise picoliter droplets of bioink onto a hydrogel substrate. This technique uses the conventional inkjet printing process with desktop inkjet printers.

- Tissue Fragments Printing – This involves a combination of bioprinting techniques with biological self-assembly to fabricate tissue structures by exploiting the intrinsic capacity of closely spaced tissue fragments. In this technique, tissues are deposited in close spatial organisation so that they merge to generate an organotypic structure.

Steps in Bioprinting

Regardless of the technique in use, Bioprinting has three major steps, which are pre-Bioprinting, Bioprinting, and post Bioprinting.

- Pre-Bioprinting – This phase encompasses all that happens prior to the actual printing, such as researchers preparing cells and mixing them with their bio-ink, or setting up a live-cell imaging system to ensure there are enough cells to print a tissue model. Before Bioprinting begins, researchers also must create a digital file for the printer to read, which is largely based on CT and MRI scans.

- Bioprinting – This is the stage where the main fabrication takes places with the use of cells, bio-inks and related equipment. Here, researchers load the printer cartridge with cells mixed into bio-ink, and proceed with printing the desired structure.

- Post-Bioprinting – This is the final stage, after the organ has been successfully fabricated. At this stage, crosslinking occurs as most structures must be crosslinked to become fully stable. Reserachers perform crosslinking by treating the fabricated structures with either ionic solutions or UV light. Cell-filled fabrications are placed inside an incubator for cultivation. The composition of the fabrication determines the type of crosslinking researchers use.

Applications of Bioprinting

The applications of Bioprinting have spread to more areas since its emergence in the medical science field. Bioprinting is commonly used to do body part and organ fabrication, repairs, and drug research.

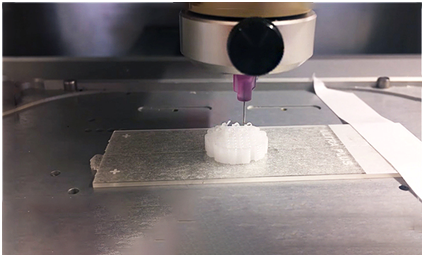

- Bone – More than 2 million people require procedures to repair damaged bones or bone defects through bone grafting every year. This number of people is greater than the population of Calgary! Recently, a new process has been identified that involves Bioprinting the whole bone and coating it with special cells and gel from the printer. This allows the entire bone to be replaced in about 3 months. Printing a bone made up of common bone tissue found in the human body takes approximately 2 hours.

An artificial bone in the process of being 3D-printed

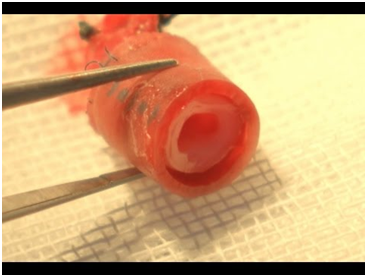

- Blood Vessels – When scientists talk about blood vessels, they are mainly referring to our veins, arteries, and capillaries. There are tens of thousands of veins, arteries and capillaries in your body, and they require repair and replacement on a regular basis. Bioprintimg technology has helped greatly in the repair of damaged capillaries with the use of Bioprinted tubes that help with nutrient transfer. Over time, they merge with the capillaries, fixing them. Another method used to repair damaged blood vessels includes using a jelly-like substance that is approximately 80% dietary fibre, known as an agarose fibre template. This template covered with hydrogel is used to construct networks exhibiting blood vessel features.

A 3D-printed blood vessel to be grafted into a primate

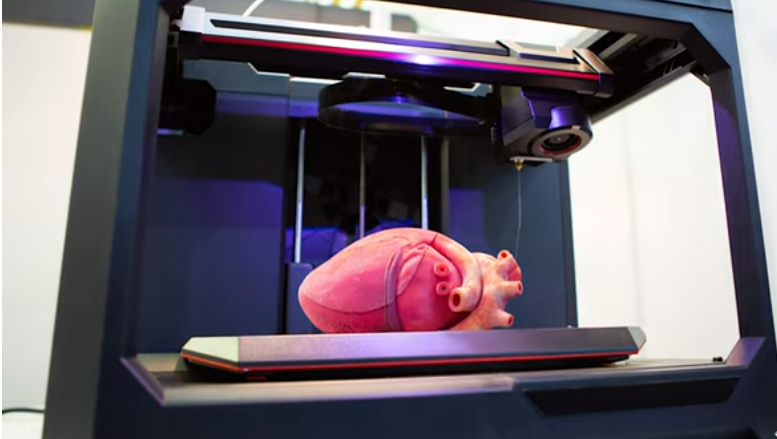

- Internal Organs – The organ transplant wait list can be fatal to many, but scientists hope that in about 20 years, through Bioprinting, the excruciating wait will be in the past. Currently, fully functional complex organs (such as hearts, kidneys, and livers) are ten years away from being created through Bioprinting. However, less complicated organs such as bladders are already possible. Less complex organs are Bioprinted using a 3D mould of the patient’s bladder, and are formed with cultivated cells from the patient’s bladder. In April 2019, the biomedical field reached a major breakthrough when a team of Israeli researchers used 3D printing technology to print an experimental heart from human tissue. That said, a fully functional heart or other more complex organs are yet to be developed through Bioprinting.

An artificial heart created through 3 D Printing

- Drug Research and Development – In drug development, Bioprinting has enabled the production of improved in vitro testing during the drug research and development stages. In recent years, the application of this technology in the pharmaceutical field has helped organizations move from testing drugs on animals to developing a range of 3D culture systems and human tissue models for more efficient drug testing purposes. Consequently, companies have been able to better identify harmful or ineffective drugs before final production. In addition, this technology has led to drastic reductions in the cost incurred from clinical trial failures.

So far, the feats recorded from the application of Bioprinting are quite impressive but researchers have barely scratched the surface. This technology is poised to further improve processes in various areas of medicine as it continues to progress.

Enjoyed this article? Visit the 4P Academy Blog for more informative pieces on a variety of fascinating topics.